Packaging Design

“Packaging” has been requiring various functions, such as protectability, distributability, and graphical design for purchasing promotion refer as Table1.

Here, protectability for products inside is the most important function of packaging and will mention in this section.

Table1. Packaging Function

| items | contents |

| Protectivity | Protective design toward distribution hazard |

| Distributionablity | Easy handling & storage |

| Graphical design | Graphical design for good look, inside product’s information |

| Universal design | Easy operation & Safety |

| Cost & Environment | 3 R, minimized packaging materials/td> |

All packaging products encounter various hazards in their distribution as Table2. These hazards occurs damage to some products. To prevent these damage, protective package has been needed. Evaluation testing like drop test, vibration test and compression test, have been conducting for the mechanical damage of each distribution hazard, Table3.

Table 2. Kind of Distribution Hazard

| Hazard | Contents |

| Mechanical | Vibration, Shock, Compression |

| Criminate | Temperature, Humidity, Atmosphere, Sunlight, etc |

| Criminate | rust, oxidation |

| Biological | mold, vermin, etc. |

Table 3. Distribution mode, Hazard and Required Test

| Hazard | Mode | Source | Required Test |

|---|---|---|---|

| Vibration | Transport | Truck,Train,Ship,Air | Vibration Test |

| Drop/Shock | Handling | Personal/Mechanical | Drop Test |

| Static Stress | Storage | Stacking | Compression Test |

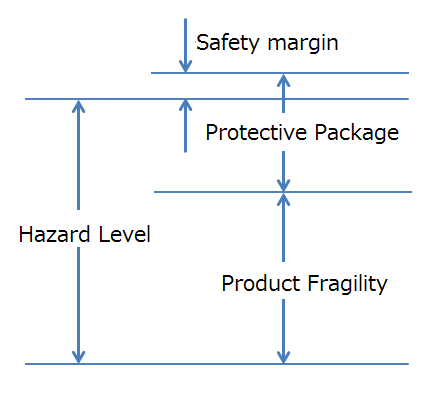

Purpose of the protective package is to protect from actual distribution hazards. It is difficult to cope with both cost and environmental effectivity. Here, we would like to introduce you the techniques for appropriate design.

Introduction

Appropriate protective design means the packaging design have a both economical and protectable function. In this section, we provide the fundamental concept of protective package design with testing and measuring......

Measuring Field Data

In this phase, we use field data logger (refer Fig.3). This device has 3D accelerometer, temperature & humid sensor within compact design. It records captured acceleration waveforms, like Fig.4 in this device. ......

Shock Fragility Test

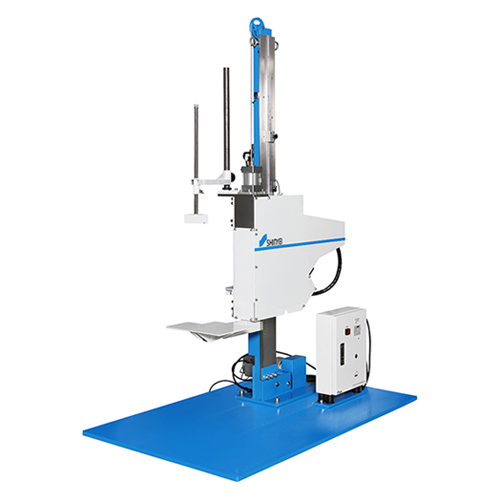

In the phase 2, we can obtain Damage Boundary Curve (see Fig.6, D.B.C.) according to JIS-Z-0119 by Shock Test Machine, Fig.5. D.B.C is indicated by,.......

Cushioning Material Test

To design the ideal cushioning material, we need to know the characteristic of these materials. In this phase, we would like to explain testing method for cushioning materials with equipment and analysis by captured data.......

Evaluation Test

As final evaluation test, drop test and vibration test are conducted. Drop tester, Fig.9, is carried out at the height you......