Introduction of Packaging Design

Appropriate protective design means the packaging design have a both economical and protectable function. In this section, we provide the fundamental concept of protective package design with testing and measuring.

Outline of appropriate packaging design

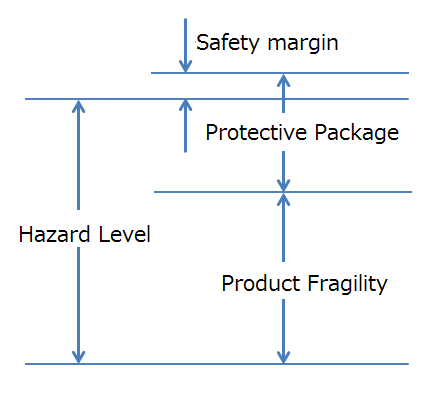

Fig.1 shows that the relationship between distribution hazard, strength of product and protective design, according to Japan Industrial Standard (JIS) Z0200. Distribution hazard means intensity level of vibration by truck board or drop height at handling, etc. overall strength of packaged product constructs with strength of product and cushioning design.

Then, appropriate packaging design should be considered the overall strength toward the distribution hazard. If this strength is under the distribution hazard, inside product may be broken in actual distribution. Then, packaging design might be over package, means high cost, if the safety margin between hazard and protectability makes bigger.

Moreover, we should consider to decrease the intensity of hazard and to improve strength of own product. Through the whole process, we can get the most effective total design, minimum cushioning material and low cost of packaged product.

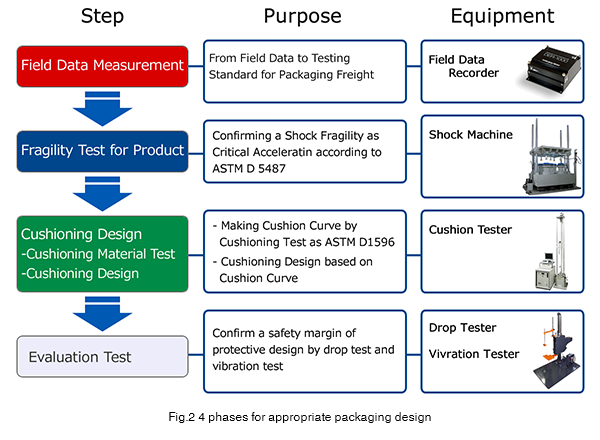

4 phases for appropriate packaging design

Regarding of 4 steps for realizing this approach, Fig.2, has been conducting with field data measuring and testing for packaged product. We have to relate the distribution hazard is as testing standard based on actual data, strength of product is as critical acceleration, and protectivity as calculating its cushioning material. Finally, evaluated testing confirms their margin. We present you each steps individually.